Kasel offers state-of-the-art process, customized, CO2-reduced and optically pure Lactic acid production plant.

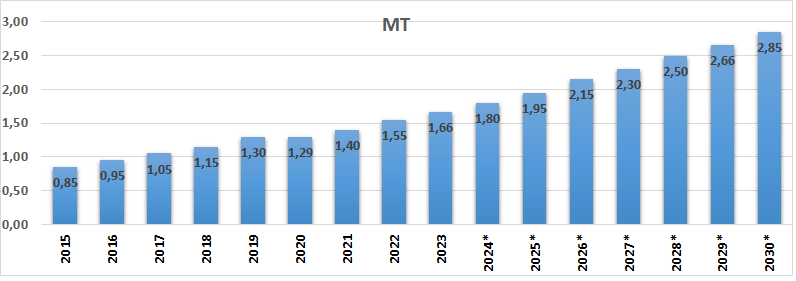

Global lactic acid production is approx. 1,8 Million tons per year in 2024, it is used in different applications in food industry, cosmetics and also in pharmaceuticals. Its market demand presents an annual growth rate between 6-8 %, which is mainly attributed to the utilization of lactic acid for the synthesis of polylactic acid (PLA) with an estimated CAGR of approx. 13-15 % between 2023 to 2035 . PLA is a biodegradable polymer used in the production of food packaging materials such as containers, wraps, single use trays, but also mulch films and garbage bags.

-Global lactic acid production:

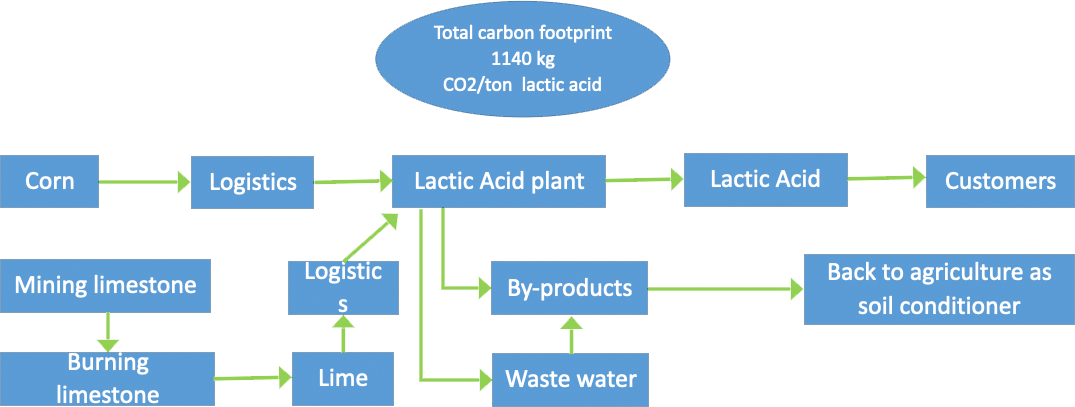

Carbon footprint lactic acid production

The infographic below shows the total impact (kg CO 2 per ton lactic acid).

Lactic Acid production currently has in average a climate footprint between 1-1,2 kg CO₂e/kg Lactic Acid (not taking in this calculation is the consumption of corn, each ton corn is binding 4 tons CO₂ in average).

Lime production

Lime is produced by burning of lime stone, to convert calcium carbonate (limestone) into calcium hydroxide (lime). This process releases CO2 and therefore has a significant contribution to the overall carbon footprint.

Lactic acid plant

This stage includes the conversion of sugar to lactic acid. The main impacts on the carbon footprint are related to the energy use (electricity and steam). In the process, lime is needed to control the pH of the fermentation. The lactic acid process generates several valuable by-products, such as gypsum, which are re-used as a soil conditioner in agriculture.